Value Measures

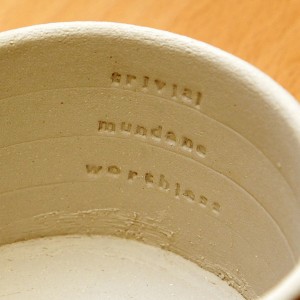

Thought I’d update you with progress on the value measures I have been making. I’ve modeled a few variations now, which are drying ready for the application of colour. You might recognise some elements from the Bygone spoon collection – twisted stems, worn edges, broken…. I’ve tried some different forms and sizes, exploring scale and proportion, and I’ve played with a couple of type faces at varying font sizes.

I think the idea is worth pursuing though there are a number of refinements to be made. I’m not happy with the shape of the bowl, generally too round (thought it works with some handle styles), I’m going to explore a more ovoid bowl form or perhaps pear shape like the apostle spoons. Also the measuring line. It’s ok indented (made by pressing an edge into the clay), but I want to see what it’s like raised. I know this seems like, and is, a small detail but I am thinking ahead to the glazing of the spoon. I want to pour glaze up to the measuring line (the glaze will subtlely change the intensity of the underlying colour and draw the eye to the measure mark) and I am thinking that a raised line will provide a better end point for the glaze. Practically, it should be easier to wipe any excess glaze from a raised line. An indented mark would probably fill with glaze, building up excess which could potentially run during subsequent firing. In anticipating and responding to these potential problems I am hoping to avoid later time consuming and costly disappointments. I’ve also been making some measuring cups based on some old metal scoops I have. Not sure about the handles yet though!

I suppose this is how an idea develops, considering and refining, reacting to problems and improving. Of course few people would probably notice these things, other makers perhaps (once developed, a keen eye rarely misses). But I just need to feel that whatever I put out there is as good as I can make it. As a sole maker you must be your own quality control no-one else has the same vested interest in your work! Sharon

Lovely work!

It is interesting to read ways in which you have to think ahead about the processes..the same applies in metalwork..

I will have to do a blog about it..working out what order to do things in metal can be one of the biggest problems..

its no good thinks about stamping words on curved surfaces..and the order of soldering…sometimes the final solder can melt the previous solders….